Take advantage of our Mazak machinery to achieve unparalleled precision in your products.

Trust us to bring your designs to life with unmatched quality.

Orders welcome now!

Mazak Flexible Manufacturing Cell Project Technology

Technical Specification of FMS Automated Line

一、Introduction to Flexible Manufacturing System (FMS)

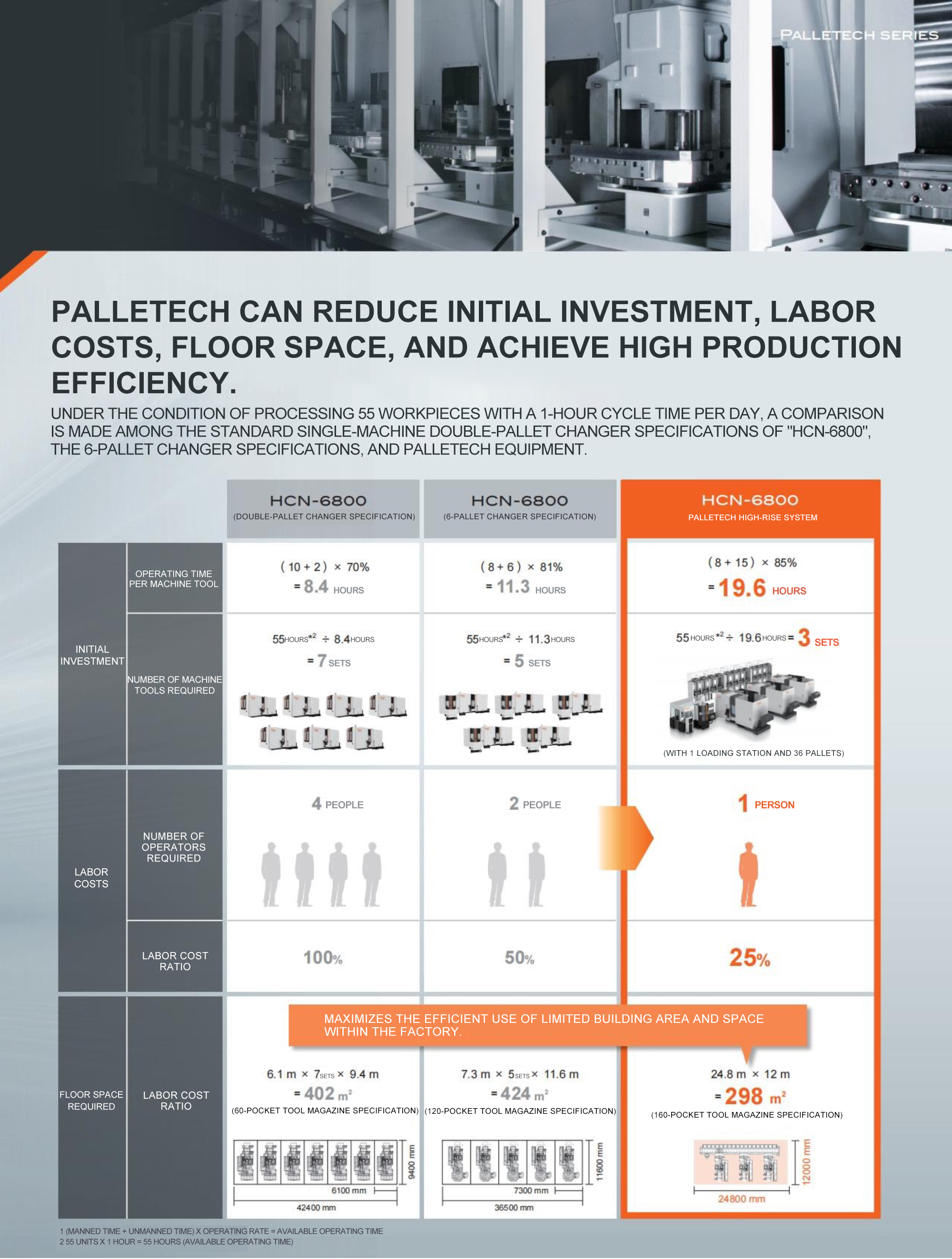

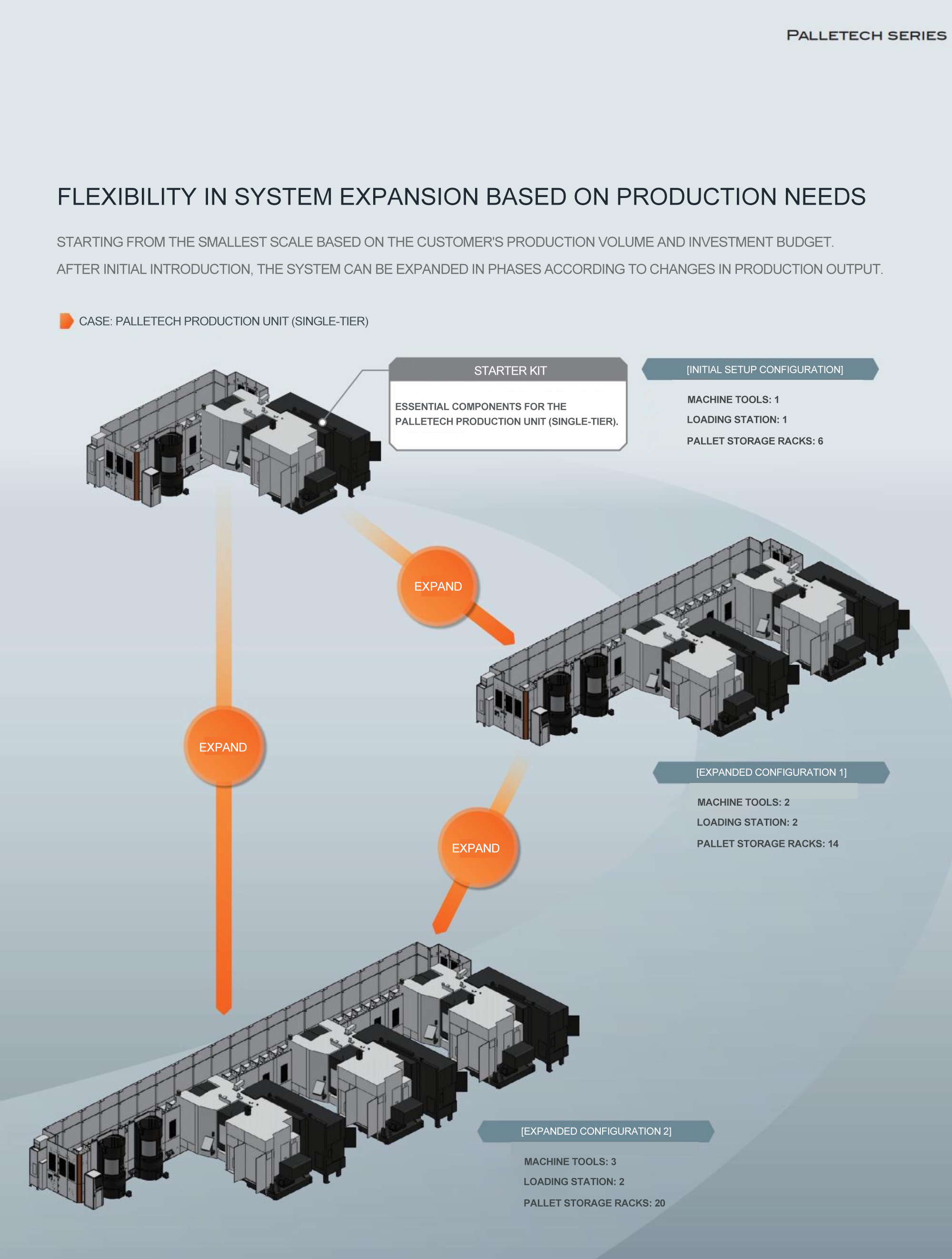

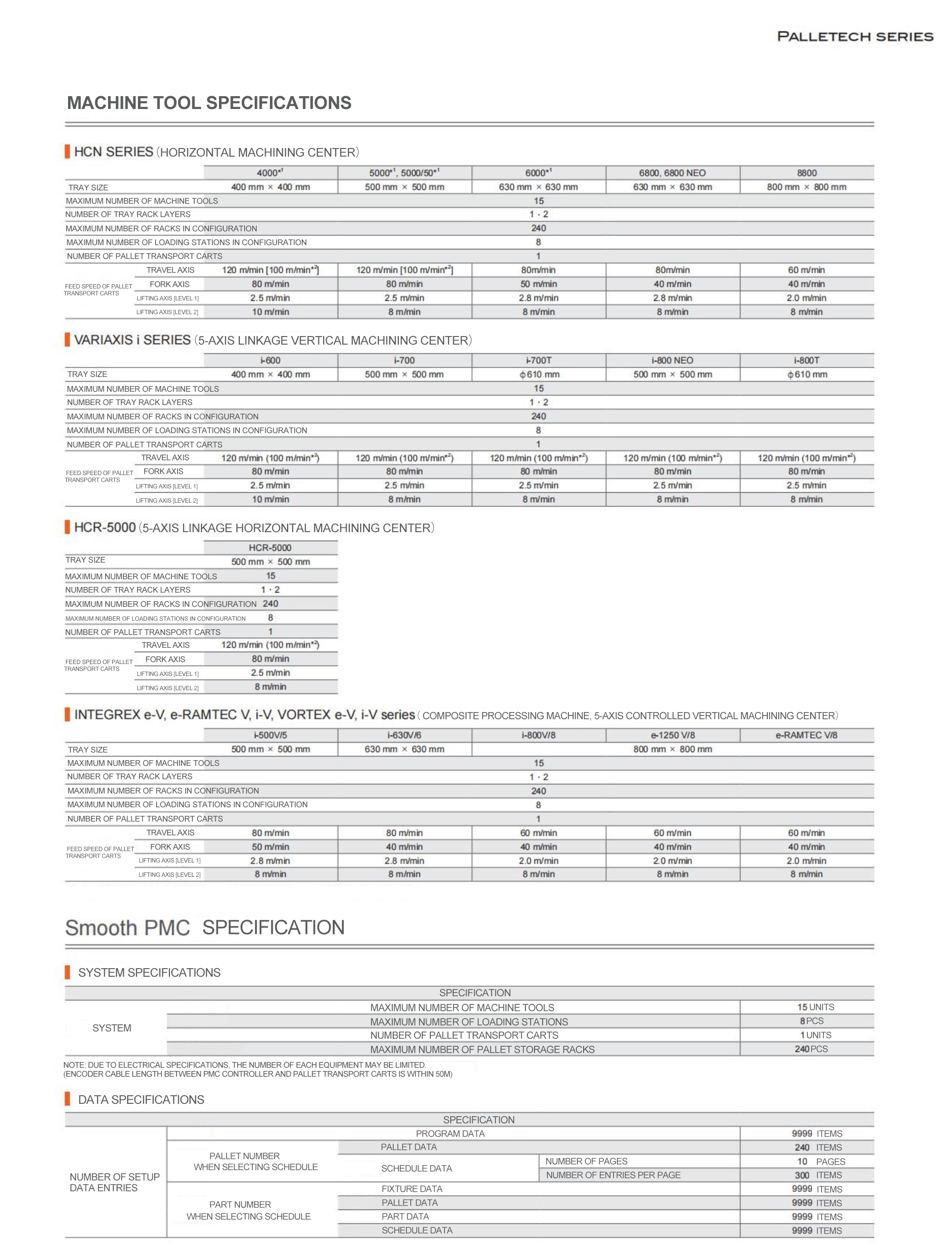

The entire FMS encompasses all necessary hardware and software for independent line operations, controlled centrally by an independent central control system. The FMS comprises 3 horizontal machining centers with a worktable size of 800X800, an automatic material handling line, 1 multi-tiered pallet magazine with 32 working pallet stations, 2 loading/unloading stations, 1 set of safety fencing, a master control system, and other auxiliary facilities.

Supported by the 3D pallet exchange station, the processing line is capable of clamping and machining a wide range of components with ease and convenience. Adaptation to new product introductions can be achieved by simply adding pallets, modifying machining programs, and changing fixtures.

Connected to the factory network via the FMS control center, it enables 24/7 continuous production. It also features a mobile hard disk docking function for program copying, and requires integration with the DNC network for direct program retrieval.

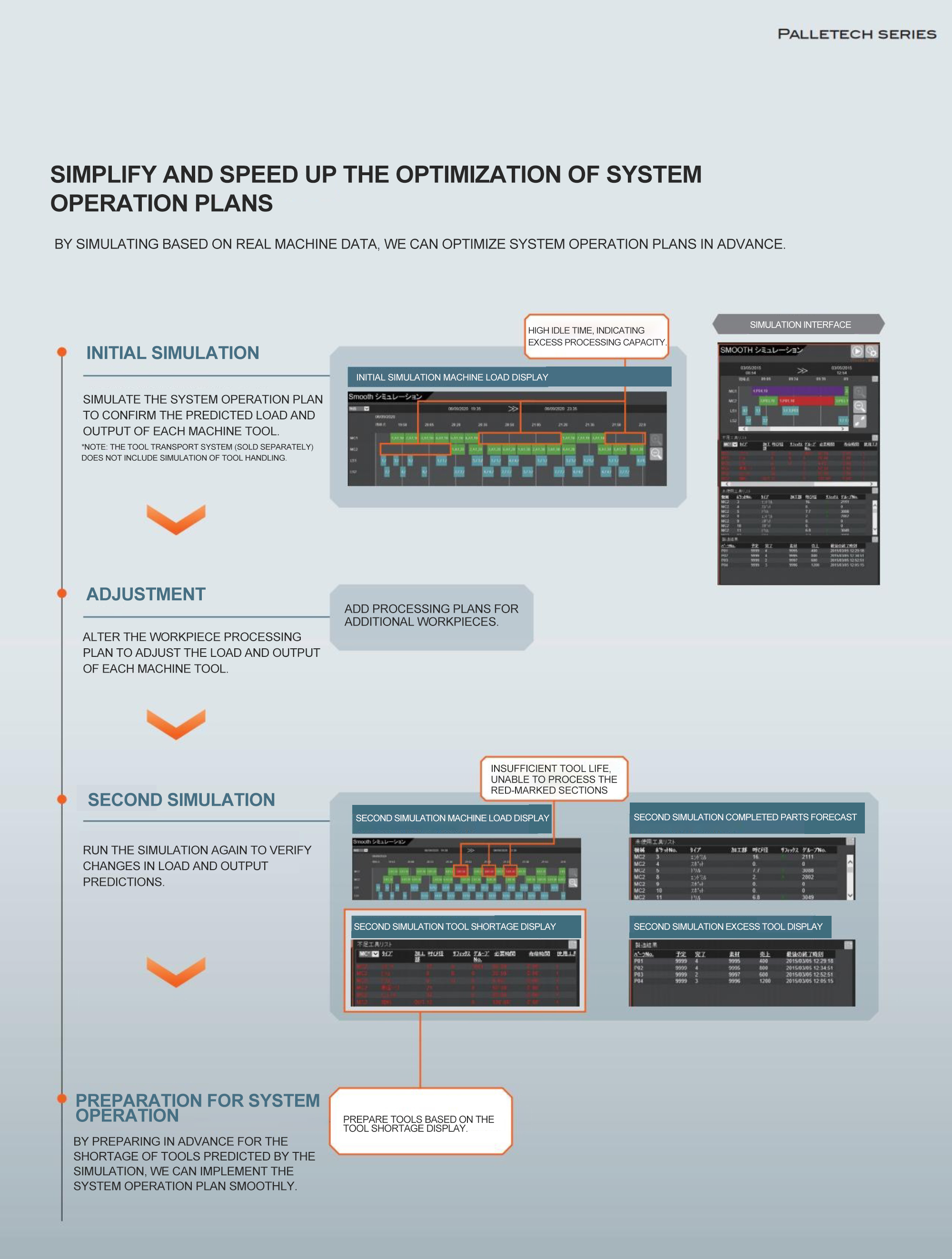

The FMS is equipped with essential control software to fulfill basic functions, including intelligent scheduling of pallets based on predetermined plans. Once a machine completes a workpiece, the master control computer automatically assigns a new task to minimize machine downtime due to part setup. It incorporates modern digital control systems such as intelligent monitoring systems.

Within the FMS, part exchange and transfer rely on a material handling trolley as the carrier. Each pallet is assigned a unique code, facilitating part clamping, and the selection of machining programs is also based on the pallet code and part type. The trolley movements are directed by commands from the master control, which can automatically verify the accuracy of pallet handling to ensure seamless system operation.

The FMS boasts sufficient static, dynamic, and thermal rigidity, as well as stable accuracy retention, achieved through the adoption of advanced technologies that guarantee excellent dynamic performance.

The control and drive system components selected for the FMS feature high precision, reliability, and fast response speeds.

The flexible manufacturing line is convenient to use, operate, and maintain, and has an aesthetically pleasing appearance. The entire flexible line is equipped with beautiful and sturdy peripheral protective covers, as well as comprehensive safety door interlocking and safety zone detection functions.

1. Flexible Line Pallet Stack

The LGMAZAK flexible line pallet stack is a mature and standard product. It adopts a steel frame design with a storage capacity designed to hold the number of work pallets required by the customer, and can be extended based on the user's future needs.

2. Coolant Disposal

A drip tray is installed under the processing pallet in the pallet stack to collect coolant during processing.

3. Fencing and Safety Equipment

There are dedicated fences around the pallet stack to ensure the safety of operators. At the same time, the pallet stack has a visible glass window to ensure that users can see the status of the storage units.

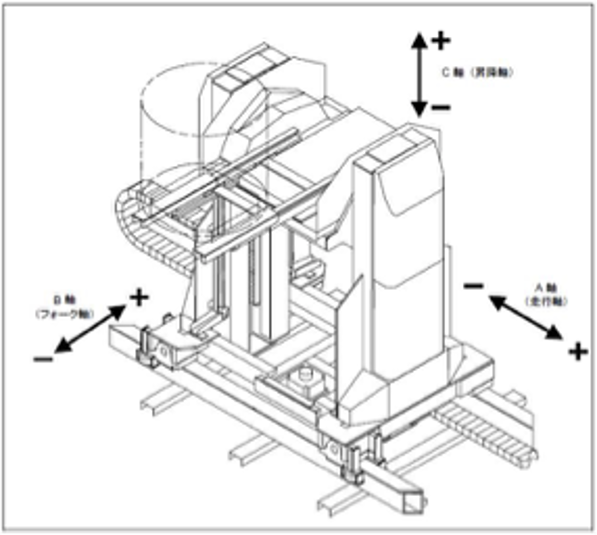

4. Logistics trolley

The flexible line uses logistics trolleys for workpiece transportation, which are controlled by three axes. The maximum speed of Axis A can reach 60 meters per minute, the maximum speed of Axis B can reach 40 meters per minute, and the maximum speed of Axis C can reach 8 meters per minute. (The above parameters are servo adjustment values)

5. Loading and Unloading Station

The loading and unloading station is equipped with a manual pallet rotary table that can be rotated manually. It can be locked at 4 intervals of 90 degrees around its longitudinal axis. Coolant is collected centrally, and the chip basin can be manually emptied. The operator-side sliding door comes with an inspection window and can be manually opened and closed. A safety gate is installed at the end of the logistics trolley passage, enabling both manual and automatic control. Before the workpiece enters the logistics trolley, there is a function to detect whether the workpiece is in the correct position for entering the logistics system.

Main Parameters of the Loading and Unloading Station (Reference Values)

Pallet Size/Weight: 800*800mm / 500kg

Maximum Working Weight: 2200kg

Maximum Workpiece Size: φ1450*1450(H)mm

Working Height of the Loading and Unloading Station: 1220mm (from the ground to the upper plane of the pallet)

6. Main Characteristics of the 800-Specification Pallet Transport Cart (Reference Values)

Maximum Loading Weight: 2700kg

A-axis Movement:

Maximum Operating Speed: 60m/min

Maximum Stroke: 50m

Drive Method: Gear/Rack, Drive Motor 3.5kw.AC

Positioning Method: Positioning - Encoder at the Motor End

Positioning Accuracy: ±2mm

Wheels: Nylon Wheels

B-axis Movement:

Maximum Operating Speed: 40m/min

Maximum Stroke: 1700mm

Drive Method: Gear/Rack, Drive Motor 1kw.AC

Positioning Method: Positioning - Encoder at the Motor End,

Positioning Accuracy: ±2mm

C-axis Movement:

Maximum Operating Speed: 8m/min

Maximum Stroke: 2080mm

Drive Method: Gear/Rack, Drive Motor 3.5kw.AC (with Brake Function)

Positioning Method: Positioning - Encoder at the Motor End

Positioning Accuracy: ±2mm

7. Control System

The LGMAZAK flexible line control system is an intelligent new FMS control system that issues commands to the machine tool through the NC device to drive the automatic operation of the machine tool. It also integrates development, manufacturing, and service through the network.

Mazak HCN8800L: It is suitable for processing brackets, cylinder blocks, box-type and shell-type products. The 8000-rpm high-torque spindle is suitable for heavy cutting of difficult-to-cut materials such as cast iron.

XYZ stroke: 140012001325mm, pallet size: 800*800mm, maximum workpiece size: 1450*1450mm

Maximum load capacity of the pallet: 2200KG